This manual serves as a comprehensive guide for the MicroLogix 1500 Programmable Controller, providing essential information for installation, configuration, and operation.

It is designed for engineers and technicians responsible for designing, programming, or troubleshooting control systems, ensuring efficient use of the controller’s features and applications.

Overview of MicroLogix 1500 Programmable Controllers

The MicroLogix 1500 is a compact and versatile programmable logic controller (PLC) designed for industrial automation applications. It is part of the Allen-Bradley MicroLogix family, offering enhanced capabilities for monitoring and controlling machinery. This controller is ideal for small to medium-sized control systems, providing reliable performance and ease of use. The MicroLogix 1500 supports a wide range of applications, including manufacturing, material handling, and building automation. Its modular design allows for scalability, enabling users to expand the system as needed. With a built-in LCD display and intuitive programming tools like RSLogix 500, the MicroLogix 1500 is a cost-effective solution for modern industrial control needs.

Key Features and Applications of MicroLogix 1500

The MicroLogix 1500 offers a robust set of features, including a built-in LCD display for status monitoring and basic programming, making it user-friendly. It supports a variety of communication protocols, facilitating integration with other devices and systems. The controller is equipped with a compact design, making it suitable for installations with limited space. Its extensive instruction set allows for complex logic execution, enabling precise control over machinery and processes. Common applications include small-scale automation, motor control, and data acquisition. The MicroLogix 1500 is also widely used in industrial automation, process control, and building management systems. Its flexibility and reliability make it a preferred choice for numerous industrial applications requiring efficient control solutions.

Installation and Setup

Installation involves mounting the controller, connecting I/O modules, and ensuring proper power supply. Software setup includes configuring communication settings and loading programs using RSLogix 500.

Hardware Installation Steps for MicroLogix 1500

Mount the MicroLogix 1500 controller on a flat surface or DIN rail, ensuring proper ventilation. Connect the power supply according to the voltage requirements specified in the manual. Install I/O modules and expansion units, securing them firmly. Connect field devices to the I/O terminals, following the wiring diagram. Configure communication ports for serial or Ethernet connectivity. Power on the controller and verify LED status indicators for proper operation. Ensure all connections are secure to prevent electrical noise or disconnections. Refer to the manual for specific torque and wiring guidelines to avoid damage. Proper installation ensures reliable performance and prevents hardware faults. Always follow safety precautions when handling electrical components.

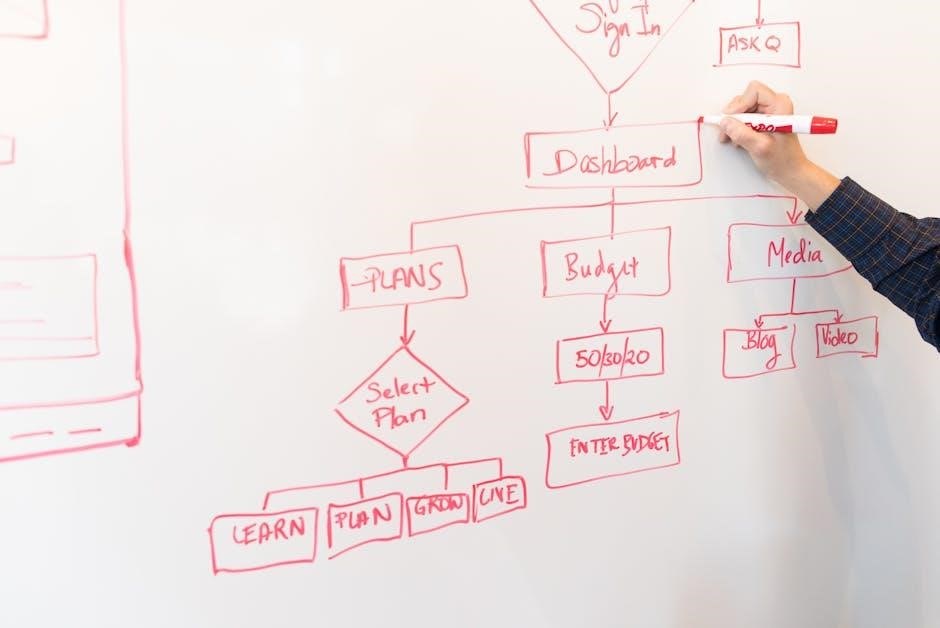

Software Configuration and Initial Setup

Download and install the RSLogix 500 programming software from the official Allen-Bradley website. Launch the software and create a new project, selecting the MicroLogix 1500 controller from the available devices. Configure the communication settings by selecting the appropriate driver, such as DH+ or Ethernet, and set the baud rate, parity, and other parameters as required. Use the “Test Communications” button to verify connectivity with the controller. Once connected, upload the default configuration or import an existing program. Set the Power Save Timeout (PST) parameter to optimize display usage. Refer to the Instruction Set Reference Manual for detailed instructions on configuring advanced settings and troubleshooting connectivity issues. Proper software setup ensures seamless operation and programming of the MicroLogix 1500.

Programming the MicroLogix 1500

Program the MicroLogix 1500 using RSLogix 500 software, creating ladder logic programs for industrial automation. Refer to the Instruction Set Reference Manual for guidance on functions and instructions.

Using RSLogix 500 Programming Software

RSLogix 500 is the primary tool for programming MicroLogix 1500 controllers. It allows users to create, edit, and monitor ladder logic programs. The software offers a user-friendly interface for designing control logic, testing programs, and troubleshooting issues. With RSLogix 500, programmers can efficiently manage projects, from initial setup to deployment. It supports various programming languages, including ladder logic, function block, and sequential function charts. The software also integrates seamlessly with other Allen-Bradley devices, ensuring compatibility and ease of use. Regular updates and comprehensive documentation make RSLogix 500 an essential tool forMicroLogix 1500 programming and automation tasks.

Understanding the Instruction Set Reference Manual

The Instruction Set Reference Manual for MicroLogix 1500 provides detailed information on the controller’s programming instructions, data files, and functions. It serves as a critical resource for understanding the controller’s capabilities and troubleshooting issues. The manual covers ladder logic instructions, function blocks, and sequential function charts, essential for programming and maintaining the controller. It also includes diagnostic techniques and parameter configurations, such as the Power Save Timeout (PST) setting. By referring to this manual, users can optimize their programming and ensure efficient operation of the MicroLogix 1500. The document is part of the MicroLogix 1200 and 1500 series, published as 1762-RM001B-US-P, and is indispensable for both novice and experienced programmers.

Troubleshooting and Maintenance

The manual provides guidance on diagnosing common issues, such as Power Save Timeout (PST) configuration and using trim pots, to ensure optimal MicroLogix 1500 performance and longevity.

Common Issues and Diagnostic Techniques

Common issues with the MicroLogix 1500 include power save timeout (PST) configuration errors and communication problems. The manual provides detailed diagnostic techniques, such as interpreting LED statuses and analyzing system logs, to identify and resolve these issues efficiently. Troubleshooting steps often involve checking network connections and verifying software configurations. Additionally, the manual emphasizes the importance of regular maintenance, such as updating firmware and cleaning hardware components, to prevent unexpected downtime. By following the outlined procedures, users can ensure smooth operation and extend the lifespan of their MicroLogix 1500 controllers. Proper training and understanding of electrical circuitry are also recommended for effective troubleshooting.

Power Save Timeout (PST) Parameter Configuration

The Power Save Timeout (PST) parameter controls the duration after which the Data Access Tool (DAT) display turns off to conserve energy. This feature is particularly useful for systems where the keypad is not frequently accessed. The PST can be configured to a range of 0 to 999 seconds, allowing users to customize energy-saving preferences based on their application needs. Proper configuration ensures optimal power management without compromising system accessibility. Detailed steps for setting the PST parameter are outlined in the manual, providing clear guidance for efficient setup and operation. This feature enhances overall system efficiency and extends the lifespan of the controller’s components. Regular reviews of the PST configuration are recommended to ensure it remains aligned with operational requirements. Always refer to the manual for specific instructions to avoid configuration errors.

Advanced Features and Tools

The MicroLogix 1500 offers advanced features like the Data Access Tool (DAT) for real-time monitoring and editing of controller data, enhancing operational efficiency and system management.

Using the Data Access Tool (DAT) Function

The Data Access Tool (DAT) function in the MicroLogix 1500 enables real-time monitoring and editing of controller data, simplifying troubleshooting and system optimization. Accessed through the RSLogix 500 software, DAT allows users to view and modify data elements such as registers, timers, and counters. This tool is particularly useful for diagnosing issues without halting production. The DAT function automatically times out after a configurable period to conserve power, ensuring energy efficiency. Proper configuration of the Power Save Timeout (PST) parameter is essential to balance data accessibility with energy savings. Detailed instructions for using DAT are provided in the MicroLogix 1500 Instruction Set Reference Manual, ensuring seamless integration into your control system.

Modem and Communication Setup with MicroLogix 1500

The MicroLogix 1500 supports various modem types, including dial-up phone modems, leased-line modems, radio modems, and line drivers, enabling remote communication. This feature allows for monitoring and controlling systems from a distance. Proper setup requires configuring the modem and ensuring compatibility with the controller. The RSLinx Classic Lite software facilitates communication setup, enabling seamless integration with the MicroLogix 1500. Users must ensure correct baud rates, parity settings, and protocol configurations to establish reliable connections. Detailed instructions for modem setup and troubleshooting are provided in the MicroLogix 1500 User Manual, ensuring efficient remote access and system management.